|

Listen to this article |

My LinkedIn inbox has been busier than usual over the last couple of weeks, since I shared an opinion piece in Forbes titled “The Reinvention of the Manufacturing Industry,” exploring how a new generation of advanced robotics is helping to democratize manufacturing, making robots affordable for companies of all sizes.

Several of my professional contacts have reached out to ask: Are collaborative robots really just for small and medium-sized companies then? We know this is not true, and so I need to offer some further explanation.

Since the inception of mechanization and mass-production processes at the start of the last century, the tools large manufacturers have used to drive competitiveness and efficiency have been geared towards using size as an advantage — economies of scale, large industrial robots for high-volume low-mix tasks, large budgets to fund efficiency programs like lean and six sigma, and the ability to outsource labor at scale to anywhere with ease.

However, these levers designed for big companies didn’t work for smaller businesses. That’s why “new age” robotics, led by collaborative robots and autonomous mobile robots (AMRs), has been a game changer for many small to midsize enterprises. But it’s not where the cobot story ends. Or ironically, even began.

For the large manufacturers, competitive pressure drove need for differentiation, which increased product variations. You can feel that on every one of their assembly lines today.

But several large manufacturers are still stuck with the old tools designed for low-mix, high-volume manufacturing in this new reality, where each of their factories and warehouses have increasingly high-mix and smaller batch sizes. Manufacturers are increasingly using advanced technologies like cobots and AMRs to make their operations nimbler and more flexible while speeding up time to market.

The origin of the cobot

Few people today realize that collaborative robots were first designed with large companies in mind.

The founders of Universal Robots (UR) examined businesses already using industrial robots and set themselves the challenge of creating something that was more easily reprogrammable for different functions across factory floors. With the competition that manufacturers face today, the need for product variations for differentiation matters greatly That feeling is palpable when I walk their assembly line.

The solution that UR came up with? The world’s first commercially viable cobot – a child of two separate university research projects.

The first project sought to create a toy robot so easy to program that a child could do it in half an hour.

The second project focused on the needs of the food industry in Denmark, which at the time was looking for a more flexible approach to automation that would allow factory employees to reconfigure production lines to accommodate new products. Engineers that tried to build that flexibility into traditional industrial robots got nowhere – it was simply impossible for workers on the factory floor to learn how to reprogram the technology that existed.

The above projects came together, and the rest, as they say, is history. The result was an easily programable, highly versatile robot.

The use of cobots in large organizations today

The global market for collaborative robots was expected to hit $1.6 billion at the end of 2023, with a compound annual growth rate of 26% to 2026, as predicted by Research and Markets. It attributed this increase to a rise in smart factories and growing demand in the Asia-Pacific region.

While it’s true that cobots are democratizing robotics, they have always been of great use to large companies. But I believe that large manufacturers are yet to fully embrace the capabilities they offer.

Solid economic drivers for increased uptake are present, including labor and skills shortages, as recent research suggests large companies have the tallest hill to climb when it comes to employee retention.

It’s no wonder that many large companies – including major global corporations like Siemens, Toyota, and Novo Nordisk – have fully integrated cobot technology to make their operations more nimble.

The time has now come for the industry to do this across the board. In a competitive world, large companies have no choice but to increase agility at every turn. Slow down, and they risk falling foul to more nimble competition.

New-age robotics offers greater efficiency and speed to market, and enterprises need to board this train today or risk getting left behind on the platform.

The integration of cobots and industrial automation

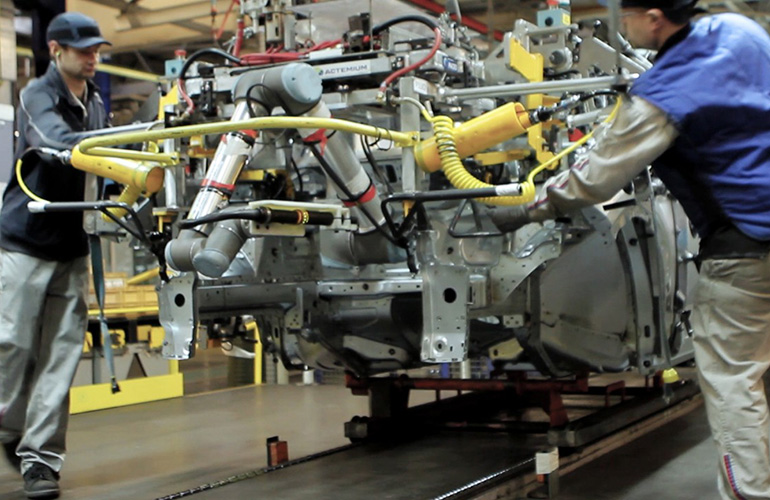

Here too, it’s really exciting to witness how collaborative robots are now working with traditional industrial robots.

Retrofitting a production line with cobots tends to be fairly straightforward, partly because of the system’s small footprint. Deeper integration between cobots and traditional industrial robots is also now often possible through the programmable logic controller (PLC).

But so much more can be done. The potential opportunities awaiting large players in 2024 are colossal, and I can’t wait to see more embracing an all-encompassing automation process in manufacturing, positioning cobots to increase productivity, product quality, and safety.

Looking to the future: AI-enabled cobots and more sophisticated applications

As machine learning and AI-enabled cobot applications become more widely available, larger businesses are perfectly positioned to leverage this cutting-edge tech to support their complex and sophisticated business needs. From quality inspection using computer vision to handling high-mix applications on the production floor, I see companies using cobots to improve costs and enhance customer satisfaction.

Cobots have become user-friendly enough for even the smallest businesses, helping to democratize manufacturing. But they are also being paired with some of the world’s most sophisticated technologies, supporting global-scale companies in becoming more productive than ever.

About the author

About the author

Ujjwal Kumar is group president of Teradyne Robotics. Over his 25-plus-year career, Kumar has successfully scaled businesses at major multinationals including General Motors, General Electric, and Honeywell.

Kumar will be giving a keynote presentation at the Robotics Summit & Expo next week. In it, he will share some lessons he has learned and how they can be applied to accelerate the transformation of industry with robotics. Registration is now open for the event, which will be on May 1 and 2 at the Boston Convention and Exhibition Center.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.