|

Listen to this article |

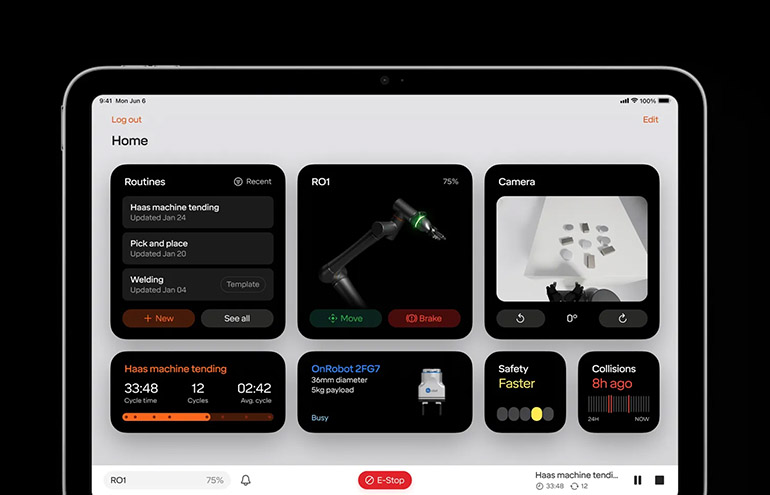

Standard Bots will use READY Robotics APIs to make its AI control software usable with multiple robot models. Source: Standard Bots

Standard Bots Co. today said that it has acquired all of the intellectual property, or IP, of READY Robotics, which had developed the ForgeOS robot-agnostic operating system. Standard Bots said the acquisition of READY Robotics’ software, patents, and trademarks will enable its own software to work across robot brands.

The New York-based company and founding partner of the New York Robotics Network said it plans to market READY’s application programming interface (API) with its own training software. It also plans to bring its user interface (UI) and artificial intelligence platform to NVIDIA Omniverse and other robot makers.

“The READY team over many years wrote some amazing software — a unified API that talks to every major robot brand,” stated Evan Beard, CEO of Standard Bots. “With this acquisition, I’m more excited than ever about what we’ll be able to offer the market in the coming months.”

READY Robotics worked on robot accessibility

READY Robotics had raised $40 million over the past eight years and had partnered with companies such as Toyota and NVIDIA. It also offered consulting services and launched a palletizing system.

However, READY reportedly had difficulty persuading robot manufacturers to work with ForgeOS, and funding plans fell through. The Columbus, Ohio-based company shut down in August.

Kal Guerin, co-founder of READY Robotics and a founding member of the New York Robotics Network, expressed optimism that Standard Bots would continue to make robots more accessible with ForgeOS.

“I am excited to see how Standard Bots will continue to democratize the robotics space using READY Robotics’ technology,” he said. “I firmly believe that Standard Bot’s goal of empowering developers to more easily use robots is essential in moving the industry forward.”

In July, Standard Bots raised $63 million in Series B funding. It did not disclose the terms of its purchase of READY Robotics assets, and it did not hire any former staffers.

The company has acquired only the IP of READY Robotics, not any hardware, Beard told The Robot Report.

“READY Robotics’ set of APIs is the perfect piece for deploying our AI platform,” he said. “By offering a unified API, UI, and AI platform for developers that works across every robot brand, we’re not just growing our company — we’re elevating the entire field.”

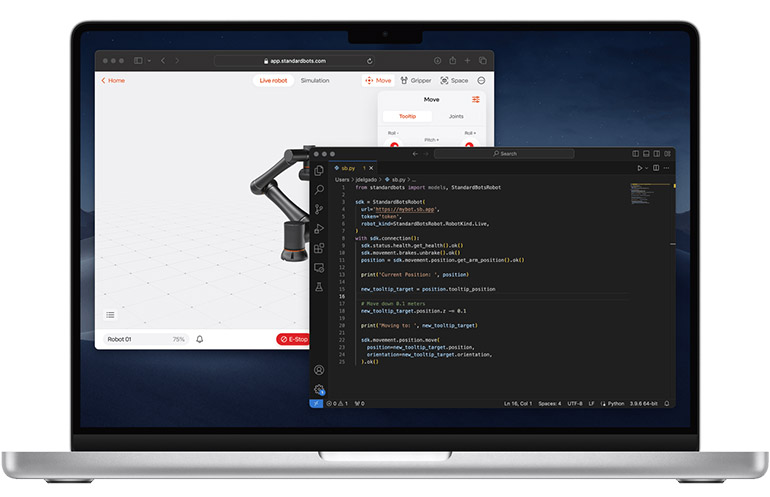

StandardOS provides developers and AI researchers with tools for building applications, integrations, and more. Source: Standard Bots

Standard Bots builds AI to ease robot training

Standard Bots said it is focused on using AI to train robots through demonstration learning. The company claimed that its vertically integrated approach will make robots easier to train and use.

“Using the latest advancements in AI, our robots are capable of both performing many new tasks and performing many existing tasks with much more versatility,” said Beard. “We’re building a platform where people can take advantage of this. Specifically, they can collect training data, fine-tune and train on top of a foundation model, build an application on top of these models, and easily deploy to any major robot brand.”

He asserted that Standard Bots’ technology can help avoid much of the time and expense currently spent on developing industrial robot applications.

“AI is such a paradigm shift in the industry,” Beard said. “But we also need better hardware to run them. A lot of robot arms don’t have APIs for good real-time control and can’t prevent an AI model from driving them into a collision.”

He cited the example of how self-driving cars have a safety layer that is above whatever a particular vehicle’s AI model is saying.

“This is an opportunity to create new robots designed from the ground up to run AI models with safety built in,” said David Golden, co-founder of Standard Bots. “The existing market is minuscule compared with the opportunity with AI. With the right AI-centric platform, it can be 100 to 1,000 times cheaper to build apps for dexterous manipulation.”

RO1 robot just one platform for foundation models

Like READY Robotics, Standard Bots has developed hardware. The RO1 arm is stronger, faster, and more accurate than competing robots and has a built-in 3D camera, according to Standard Bots.

If Standard Bots has a robot arm to go with its AI platform, why does it need READY Robotics API?

“There are shops that will only use FANUC systems,” Beard acknowledged. “In our view, we want to spread our technology as fast as possible. The way to do that is to be robot-agnostic.”

Standard Bots has already developed applications for its robot, which is made in the U.S. and available for sale or through a robotics-as-a-service (RaaS) model.

“At Fabtech, we launched welding, and at IMTS, we launched a machine-tending solution. At Pack Expo this week, we’re demonstrating palletizing,” said Beard. “Right now, we have a best-in-class solution for each use case. And using AI, our solutions will stand alone in the market in terms of capability and versatility.”

“We’re seeing really strong growth, from Fortune 500 customers and NASA all the way down to smaller companies that need one or two robots,” he added. “It all comes down to ease of setup. You don’t have to be an expert. Nobody else is providing this end-to-end control.”

Research labs working on foundation models are already using Standard Bots’ integrated systems, Beard said. The company also provides handheld devices for imitation learning, allowing a robot to generalize behavior and correct its motion in real time.

“We’re providing the tools to collect data, fine-tune it, and build applications on it,” Beard said. “Imagine a robot unloading a UPS truck. We can help end customers fine-tune a foundation model, create, and deploy an application for this. And since all our robots can be connected, there’s closed-loop improvement.”