|

Listen to this article |

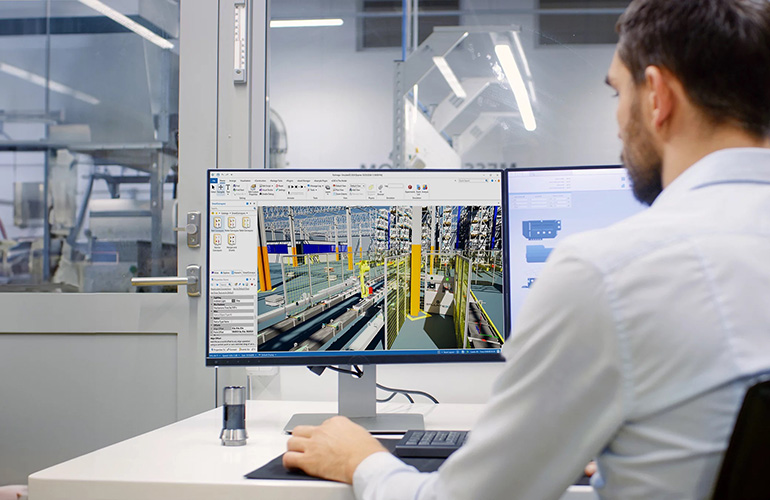

With Rockwell Automation’s Emulate3D digital twin software, users can identify potential control issues preemptively, saving valuable time and resources during implementation. | Source: Rockwell Automation

Rockwell Automation is integrating NVIDIA Omniverse application programming interfaces (APIs) into its Emulate3D digital twin software. Rockwell Automation said this integration will enhance factory operations through artificial intelligence (AI) and physics-based simulation technology.

Rockwell Automation’s Emulate3D software uses NVIDIA Omniverse APIs to create factory-scale dynamic digital twins based on OpenUSD interoperability and NVIDIA RTX rendering technologies. While visualization was previously possible, this enhancement enables true emulation and dynamic testing of multiple machines within a system, Rockwell said. The integration is planned for early 2025 and will enable improved visualization and simulation capabilities for manufacturing environments.

“Our integration of Emulate3D with NVIDIA Omniverse marks a significant leap forward in bringing autonomous operations to life,” said Blake Moret, chairman and CEO of Rockwell Automation. “By combining our deep industrial expertise with NVIDIA’s cutting-edge technology, we’re helping our customers achieve new levels of efficiency, innovation, and collaboration in their manufacturing processes.”

Rockwell Automation is dedicated to industrial automation and digital transformation. The Milwaukee, Wis.-based company employs 27,000 people in more than 100 countries as of fiscal year-end 2024.

The company’s Emulate3D digital twin software helps users preemptively identify potential control issues, saving time and resources during implementation. Plant personnel receive additional support by having a virtual space to train on new systems, predict future performance, and simulate line changes without real-world consequences.

NVIDIA Omniverse enables digital twins at scale, Rockwell said

Digital twins enhance equipment development and control testing through simulation models and emulation, reducing startup time and risk. As equipment is connected into lines, models scale and challenges arise from siloed expertise and integration issues between separately engineered components.

A system-level perspective, including interoperability across machines, can solve these issues, but requires collaboration for system-level testing. As lines scale, larger digital twins require more computational power, risking bottlenecks. Automation leaders need scalable solutions to achieve full factory-scale models, building on digital twin successes.

By using NVIDIA Omniverse, Emulate3D will allow multiple dynamic digital twins to be combined and visualized as a complete factory through a web app. This vendor-agnostic, scalable approach aims to address the growing need for factory-scale digital twins created by engineers collaborating across various teams. Rockwell Automation’s expertise in industrial automation and Emulate3D’s comprehensive modeling capabilities pair with the NVIDIA Omniverse platform to enable real-time collaboration at scale.

Rockwell said manufacturers will benefit from:

- Hyperscale capabilities through Emulate3D’s multi-model technology

- Cloud-based deployment options for maximum flexibility

- Vendor-agnostic connectivity to a wide range of 3D applications

- A unified web app for stakeholder visualization

NVIDIA Omniverse lets developers integrate various factory layers into a comprehensive model, combining architectural software with industrial digital twins. This enables greater coordination across industrial design and operation. Built for scalability, Omniverse’s Universal Scene Description (OpenUSD) foundations and cloud deployments grow alongside projects. This means it helps meet customer demands for even the most complex endeavors.

Rockwell said this system is particularly valuable for industries with complex, hybrid applications. These include consumer packaged goods, food and beverage, life sciences, semiconductor manufacturing, automotive, and material handling.