|

Listen to this article |

Businesses are adopting automation to mitigate labor shortages and increase productivity, found HowToRobot. Source: Adobe Stock

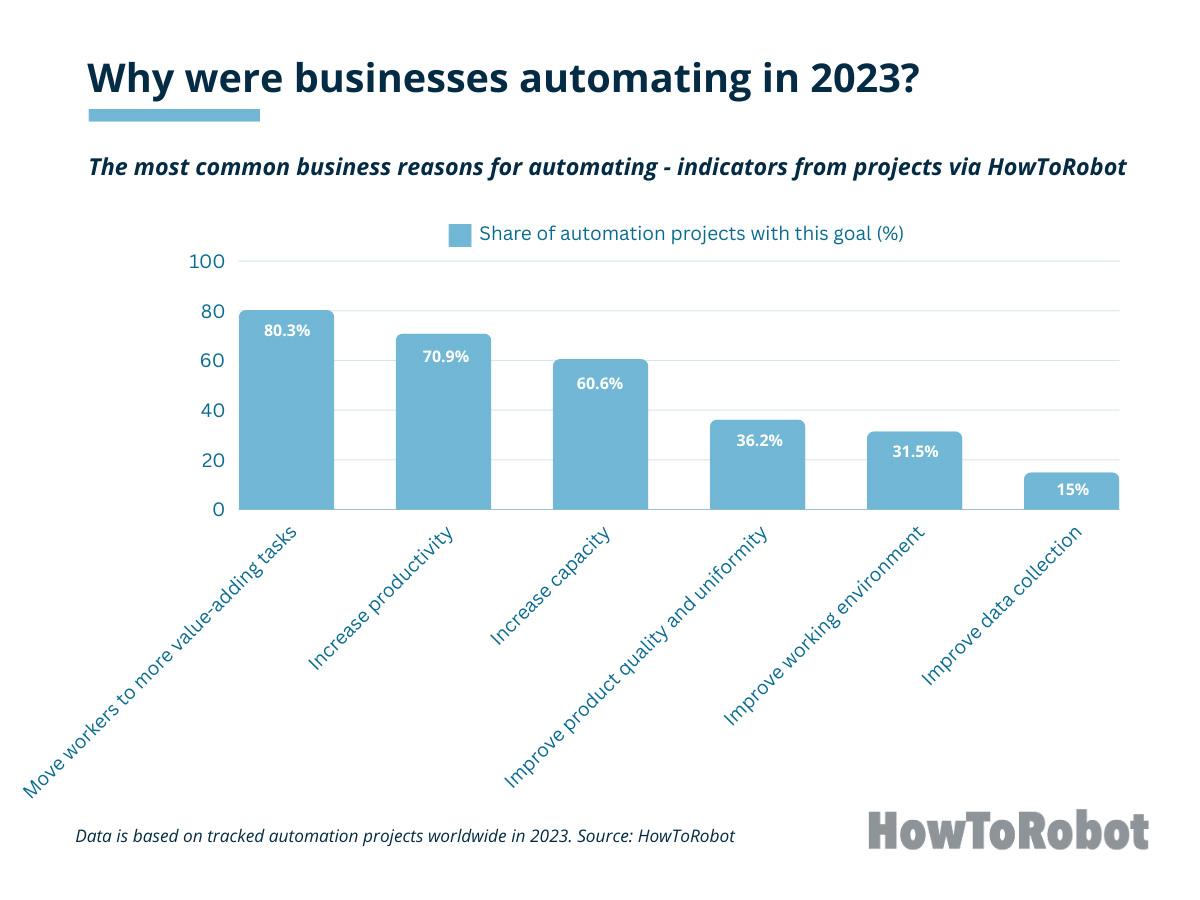

Businesses are adopting automation not to replace workers but to augment scarce labor, according to data that HowToRobot released yesterday. It found that 80% of respondents said their projects are intended to free employees from manual tasks and move them to other more value-adding activities.

The Denmark-based provider of a global automation market platform said its findings confirm that businesses are seeing robotics and automation as a supplement to human labor, not as a replacement.

“From our daily conversations with manufacturers worldwide, it’s clear that the lack of labor has been the driving factor behind business decisions to automate in 2023,” said Søren Peters, CEO of HowToRobot, in a release.

“By automating the most cumbersome tasks, businesses have been freeing employees to take on other tasks needed to maintain production levels and fulfill customer orders,” he said. “Not one we asked did this because they wanted to lay off people.”

Labor shortages peaked in North America and Europe in the spring of 2022 as the COVID-19 pandemic eased, said HowToRobot. These labor shortages continued at elevated levels in 2023.

In the U.S., manufacturing job opening rates averaged 4.5% in 2023, almost twice the pre-pandemic average of 2.8% from 2013 to 2019, according to the U.S. Bureau of Labor Statistics (BLS).

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Labor shortages prevent productivity growth

The second biggest motivation for automating in 2023 was to increase productivity. HowToRobot reported that 70.9% of respondents’ projects had this goal.

Robots can improve productivity by reducing the labor hours needed to create the same output, it said. This enables companies to increase wages, reduce prices, and grow their profits, leading to stronger economic growth.

With high inflation levels over the past three years, productivity has been particularly important for businesses, said Peters.

Labor shortages have also constrained businesses’ ability to expand production capacity with manual labor, further increasing demand for automation, said HowToRobot. In 2023, 60.6% of automation projects sought to increase capacity, making it the third-largest motivation to automate, the company noted.

Hourly compensation in U.S. manufacturing alone grew by 18% between 2019 and 2023, according to BLS data.

“When costs are rising rapidly, what do you do as a business?” said Peters. “Either you cut down or invest in areas that increase your productivity.”

“We are seeing that many of those who had the foresight – and funds – to invest in automation are now coming out on top,” he added. “They are more competitive and can afford to pay their employees better.”

Moving workers to more value-added tasks, productivity, and capacity were top reasons for adopting automation.. | Source: HowToRobot

Product quality, working conditions matter, finds HowToRobot

About a third — 36.2% — of automation projects last year sought to improve product quality and uniformity with automation, making it a moderately important business goal, said HowToRobot.

Manual operations during certain parts of the manufacturing process can result in varying product quality and uniformity, which can lead to more customer claims and resource waste. Peters said that businesses are increasingly focusing on offsetting high input costs.

“We also see a growing awareness about the environmental impact of wasteful processes and how robots and automation can help reduce the ecological footprint of manufacturing operations,” Peters said.

Many businesses also looked for automation to improve their working environments. Last year, 31.5% of automation projects had this goal, said HowToRobot.

For example, businesses can automate demanding tasks that involve repetitive motion, heavy lifting, or hazardous environments. This can free up employees to take on less backbreaking and more meaningful tasks, HowToRobot said.

“It’s becoming clear for a growing number of businesses that investing in employee well-being also involves automation,” Peters said.

Peters has said that businesses shouldn’t wait to plan future robotics investments. According to HowToRobot, the time from starting an automation project to signing an agreement with a vendor can vary from a few weeks to more than a year.

The earlier a business starts the process, the sooner it can reap the benefits of automation, the company said.