|

Listen to this article |

Kawasaki Robotics (USA) Inc. today said it will demonstrate the latest additions to its portfolio, including the CL Series collaborative robots, at IMTS next week. The Wixom, Mich.-based company said it has continued to refine the cobots’ utility for applications such as welding, machine tending, and material removal.

“Kawasaki Robotics is committed to delivering the advanced automation technology manufacturers need to maintain production schedules without having to compromise quality or safety,” stated Seiji Amazawa, president of Kawasaki Robotics. “We lead the robotics industry by collaborating with innovative partners such as AMT, Hurco, Wauseon Machine, and NEURA Robotics, integrating our technology with theirs to harness the best in human ingenuity.”

NEURA Robotics partnered with Kawasaki to develop the CL Series, which the companies claimed offers industrial-scale performance and speed without compromising the safety and flexibility advantages of human-robot collaboration.

“It’s all about lowering the barriers to entry,” Zachary Thoma, a former integrator and regional sales manager at Kawasaki Robotics, told The Robot Report. “Since Automate, we’ve been making sure that our products are as user-friendly as possible and are working with partners to ensure that customers don’t need a Ph.D. to make the CL Series work.”

“I’ve been critical of cobots over my career, but we want to offer the best-value machine for repeatability, speed, ease of use, and package price,” he added. ”We test our core technologies in parallel in Japan, the U.S., and Germany.”

CL Series offers repeatability with flexibility

“By providing advanced capabilities along with industrial scale performance and speed as standard features, we boost productivity, improve product quality and worker safety, and reduce rework requirements,” Amazawa asserted. “Our entirely new way and agile approach to collaborative robots enables manufacturers to more easily address labor shortages while yielding excellent return on investment.”

The CL Series supports a variety of payloads and reach from 3 kg/590 mm (6.6 lb./23.2 in.) to 10 kg/1,000 mm (22 lb./39.3 in.). Kawasaki said it expects models with higher payloads such as 15 kg (33 lb.) to come to market within the next year.

Built with components such as integrated 24-bit encoders, the collaborative robots operate at a speed of 200°/s and a repeatability of +/– 0.02 mm. The CL Series also also has free mounting orientations, a small footprint, and IP66 classification provide flexibility, said Kawasaki.

The cobots have an intuitive user interface, plus proprietary safety limits and collision detection for reliable operations alongside human workers, according to the company.

For “industrial collaboration,” the CL robots have the same casing as Kawasaki Robotics’ industrial robot arms. This enables them to operate without protective covers in crowded and harsh environments that may not be suitable for other cobots.

“There are no collaborative robots — only collaborative applications,” said Thoma. “The robot doesn’t determine suitability; the application does. Is the process slow, does it require flexibility or accuracy/repeatability, is the payload heavy?”

Kawasaki to demonstrate applications with partners

Kawasaki Robotics plans to demonstrate its entire CL Series and other automation in Chicago. For example, a CL110 cobot will tend an upgraded Wauseon Machine 1004EL Electric End Forming Machine.

“IMTS attendees can see pick-and-place demo,” Gilles Renard, a robotics engineer and applications engineering team leader at Kawasaki Robotics, told The Robot Report. “Three big improvements of the past six months were in flexibility for arc welding, palletizing software capabilities, and communication from the PLC.”

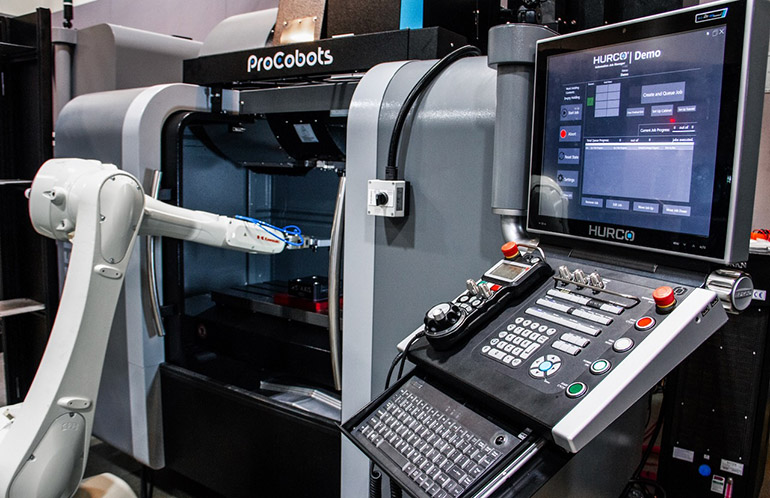

Kawasaki will also show at Booth 236520 a modular shelf system for part feeding that it developed with Hurco. It will include a Kawasaki RS013N robot, 16 workpieces — four fixtured to pallets and 12 held in 5th Axis LiteVises — and a Hurco VM15Di CNC machine, all operated with Hurco’s WinMax CNC Controls.

That system was designed to keep up with customer demand for high-mix, low-volume parts manufacturing without the need to learn how to program a robot.

“We want to provide turnkey machine tending out of the box,” asserted Thoma. “By partnering with a premium machining providers, we want to provide premier support and reliability without premier costs.”

In addition, an interactive CL108 cobot display will show how the CL Series Zero-G mode allows for hand guiding and recording programs with a light touch, said the unit of Minato City, Japan-based Kawasaki Heavy Industries. Saved parameters improve setup consistency and reduce setup errors, it said.

“The hands-on demo will allow people to feel the sensitivity of Zero-G hand guidance and the ease of teaching points,” Renard said. “They will have a feel for an industrial robot in a collaborative space.”

Other Kawasaki robots on display at IMTS

Kawasaki will exhibit its new BA013N and BA013L industrial robots with built-in intelligence, adaptive arc welding, and real-time path modulation (RTPM) capabilities. Also for welding, K-Positioners can help automate workpiece movement to optimize the position of welding torches and reduce cycle times.

The company developed the RoboFin system with AMT and NEFF Automation for material removal and finishing. It can handle diverse materials and surface types, increase abrasive life up to 3X, and improve consistency and quality, said Kawasaki.

The K-Track linear axes are intended to simplify reconfiguration of production lines by reducing the number of robots needed for a particular task.

Finally, Kawasaki Robotics plans to show its ASTORINO educational robot in Booth 121415 in the IMTS Smartforce Student Summit.

“The cobot space is competitive,” acknowledged Thoma. “But our robot has precise repeatability along the same lines as an industrial robot, and the robust nature of our robot is part of Kawasaki’s DNA. What sets us apart in the end is the company and the people who take a personal interest in making sure that customers get the right tool for the job.”