|

Listen to this article |

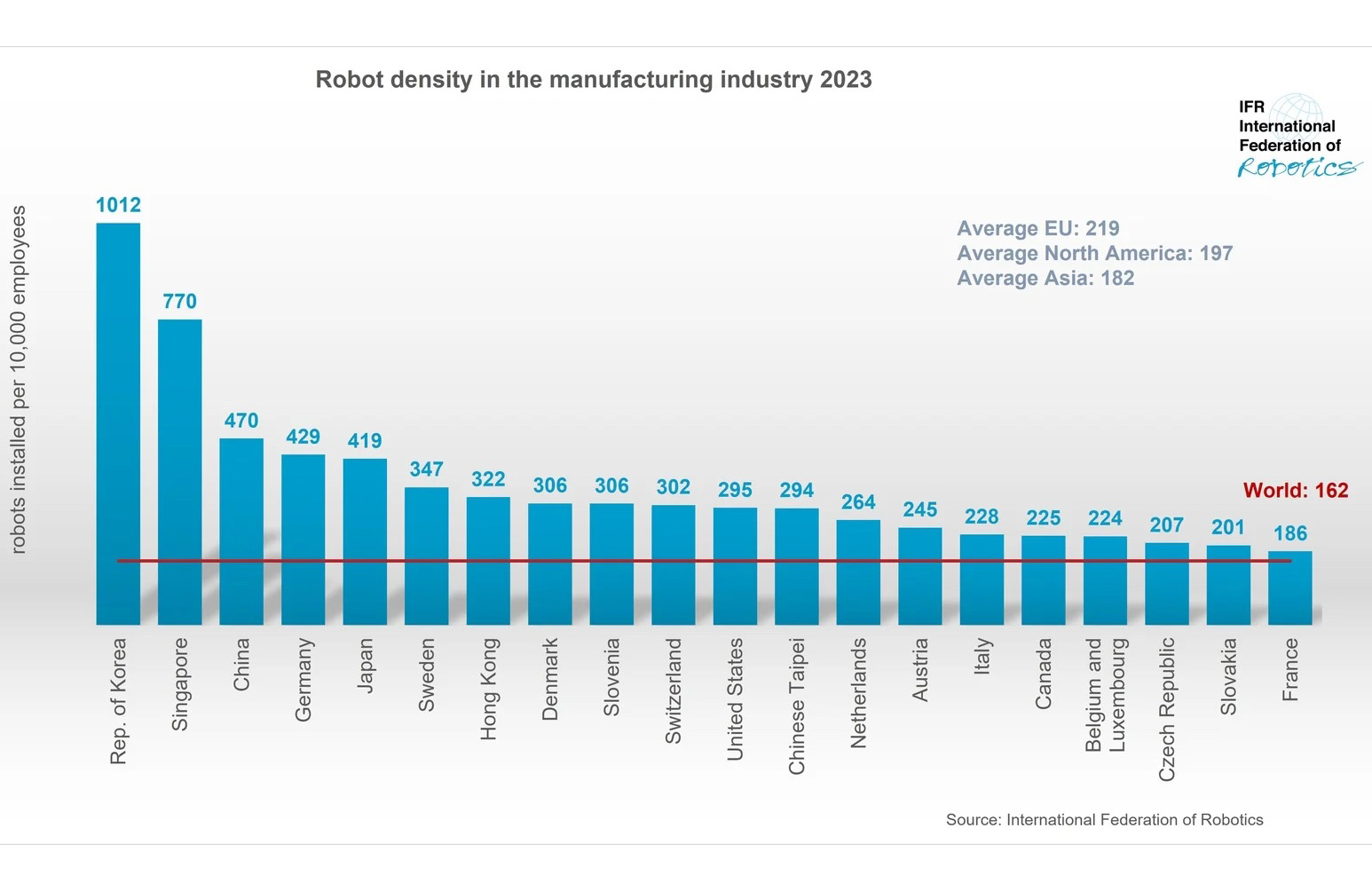

Factories worldwide are continuing to adopt more robots, according to the International Federation of Robotics, or IFR. The new global average robot density reached a record 162 units per 10,000 employees in 2023 — more than double the 74 unit average measured only seven years ago.

The Frankfurt, Germany-based IFR noted the growth in its “World Robotics 2024″ report.

“Robot density serves as a barometer to track the degree of automation adoption in the manufacturing industry around the world,” stated Takayuki Ito, the IFR’s new president. “This year’s runner-up is China, which ranks third worldwide behind Korea and Singapore, but right up with Germany and Japan.”

Europe leads in regional robot density

When breaking these numbers down by region, the European Union had the highest robot density, with 219 units installed per 10,000 employees. This is an increase of 5.2% from 2022, with Germany, Sweden, Denmark, and Slovenia in the global Top 10.

North America followed with 197 units per 10,000 employees, up 4.2% from 2022.

Asia has 182 units per 10,000 people employed in manufacturing — an increase of 7.6%. The economies of Korea, Singapore, mainland China, and Japan were among the top ten most automated countries in 2023.

Founded in 1987, IFR aims to connect the world of robotics around the globe. It’s institutional members come from the robotics industry, national or international industry associations, and research and development institutes. The non-profit organization directly represents more than 90 members from over 20 countries.

IFR lists countries that are top robot users

The Republic of Korea was the world’s No. 1 adopter of industrial robots in 2023, with 1,012 robots per 10,000 employees. Robot density has increased by 5% in the country on average each year since 2018.

With a world-renowned electronics industry and a strong automotive industry, the Korean economy relies on the two largest customers for industrial robots, said the IFR.

Singapore followed with 770 robots per 10,000 employees. It is a small country with a very low number of employees in the manufacturing industry, so it can reach a high density with a relatively small operational stock.

China took third place in 2023, surpassing Germany and Japan for the first time. It has been heavily investing in automation technology in recent years. This investment seems to have paid off, the IFR noted, as the People’s Republic of China reached a high robot density of 470 robots per 10,000 employees, compared with 402 units in 2022.

“China’s massive investment in automation technology has achieved this high robot density despite a huge manufacturing workforce of around 37 million people,” Ito said. “Robot density serves as a useful barometer for comparing the level of automation in manufacturing between countries.”

Germany and Japan followed China, in fourth and fifth place respectively. Germany has 429 robots per 10,000 employees, and its robot density has grown by 5% CAGR since 2018.

Japan is close behind with 419 units. The robot density of the world’s predominant robotics manufacturing country has grown by 7% on average each year from 2018 to 2023.

The U.S. reached 295 units per 10,000 employees in 2023, falling just outside of the top 10 by ranking eleventh in the world. While it has been increasing its robot density, the U.S. had 285 units per 10,000 robots installed in 2022.

The U.S. hasn’t been able to keep up with the rest of the world’s pace. In 2022, it was the 10th most automated country worldwide, and in 2021, it was the ninth most automated country.