|

Listen to this article |

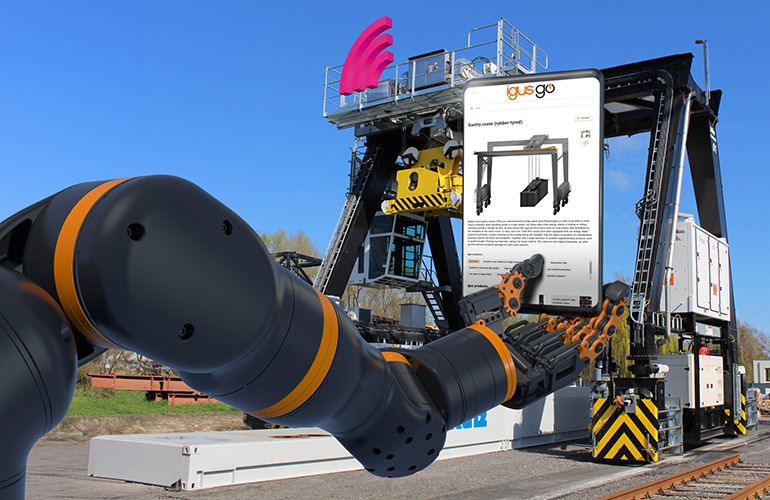

igus relies on AI-supported low-cost robotics, smart maintenance, and AI-based online tools like the igusGO app to get customer applications ready for Industry 4.0. | Source: igus

igus GmbH will be introducing igusGO, an AI-powered app, alongside a series of smart sensor technologies at Hannover Messe. The company said it designed its latest sensor technologies “to streamline maintenance and optimize production processes for the lubrication-free industry of tomorrow.”

The Cologne, Germany-based company said igusGO is the centerpiece of its innovation. The app uses artificial intelligence to instantly identify optimization opportunities for designers using motion plastics.

The app simplifies the selection process without the need for traditional catalog browsing, according to igus. The company said the app reflects its commitment to enhancing operational reliability and cost-efficiency across various applications, from heavy-duty machinery to everyday devices.

“Our aim with igusGO and our suite of smart products is to navigate the vast potential of motion plastics with unprecedented efficiency and transparency,” stated Tobias Vogel, CEO of plain bearings and linear technology at igus.

Michael Blass, CEO of E-Chain Systems, added that innovations such as superwise, a digital service for comprehensive maintenance insights, can bolster competitiveness during challenging times.

“By merging our innovative products with digital services, we’re demonstrating how our motion plastics can significantly enhance a wide array of applications, driving them towards a more sustainable and technologically advanced future,” he said.

The benefits of polymer bearings

igus cited its collaboration with RWTH Aachen University as an example of the economic and ecological advantages that its polymer bearings offer. They could result in potential savings of up to $14.9 million (€14 million) annually.

Polymer bearings can also provide substantial CO2 reductions, as exemplified by Heineken Brazil’s savings of 396.8 lb. (180 kg) of CO2 equivalents per year through the switch to polymer bearings, said igus.

igus also offers affordable, precise automation

igus also offers low-cost automation. The Rumford, R.I.-based company has introduced user-friendly robotics with AI-based voice and gesture control, exemplified by the ReBeL collaborative robot and its plug-and-play capabilities.

The company won a 2024 RBR50 Robotics Innovation Award for its $2,760 finger gripper for the cobot. igus said these advancements are complemented by its RBTX online marketplace, which facilitates access to compatible accessories and promotes an inclusive approach to automation for companies of all sizes.

Earlier this year, igus launched a double-shaft stepper motor for its drylin linear technology. The company said the double-shaft design allows for precise control over linear motion, enabling a range of automation, transfer-station, and format-adjustment applications.

Editor’s note: At the Robotics Summit & Expo, which will be held in Boston, igus will exhibit at Booth 414. The company will also participate in a session on “Democratizing Automation” at 2:45 p.m. EDT on Wednesday, May 1. Register now to attend.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.

Learn from Agility Robotics, Amazon, Disney, Teradyne and many more.