|

Listen to this article |

Shanghai-based Fourier today launched GR-2, the latest generation of its GRx humanoid robot series. The company has upgraded its hardware, design, and software.

“GR-2 is a big step into the future of humanoid robotics,” stated Alex Gu, CEO of Fourier. “We’re passionate about building the most intuitive embodied agent for AI, allowing it to engage with the physical world in ways like never before. Fourier is excited to have developers, researchers, and enterprises join us on this incredible journey.”

This announcement followed the company‘s rebranding from Fourier Intelligence to Fourier earlier this year, and the GR-2 release builds on the production release of the first-generation GR-1 in late 2023.

Fourier improves hardware design

The GR-2 stands 175 cm (68.9 in.) tall and weighs 63 kg (139 lb.), whereas the GR-1 is 165 cm (65 in.) tall and weighs 55 kg (121 lb.). GR-2 offers 53 degrees of freedom and a single-arm load capacity of 3 kg (6.6 lb.).

A new feature of Fourier’s humanoid is a detachable battery with twice the capacity of its predecessor and a runtime of up to two hours. Since the battery is now swappable, users will be able to swap batteries quickly and return GR-2 to work.

GR-2 features an integrated cabling design for power and communication transmission, allowing concealed wires and more compact packaging. The efficient layout optimizes space for easier modularization and greater adaptiveness for application-oriented customization.

To simplify the control system and reduce maintenance, Fourier redesigned GR-2’s joint configuration, shifting from a parallel to a serial structure. It said this improves debugging, lowers manufacturing costs, and enhances the robot’s ability to rapidly learn and transition from AI simulation to real-world applications.

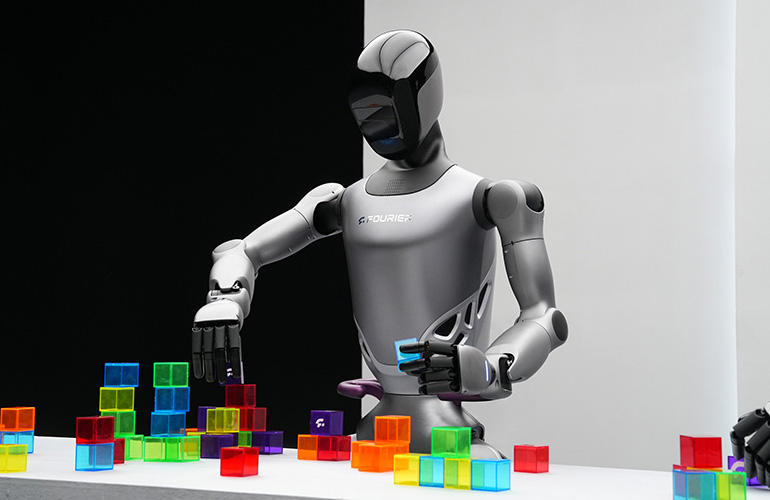

Dexterous hands have 12 degrees of freedom

The 12-DoF Dexterous Hand is equipped with six array-type tactile sensors. | Credit: Fourier

The robot includes hands with 12 degrees of freedom, doubling the dexterity of previous models. The hands are designed to mirror the flexibility of human physiology and offer greater precision in the tasks that the robot will be asked to complete, said Fourier.

The fingers on GR-2 also have six array-type tactile sensors that sense force and can identify object shapes and materials. This enables new algorithms to optimize parts handling, the company said.

Supporting multiple upper-limb teaching modes—virtual reality remote control, lead-through programming, and direct command—GR-2 can record a comprehensive set of operational data, from motion paths to tactile responses. Fourier said it expects robust data collection to bridge the gap between virtual models and real-world applications, pushing the boundaries of robot training and deployment further.

FSA 2.0 powers dynamic mobility

To optimize its movement, Fourier developed seven distinct Fourier Smart Actuators (FSA) for GR-2, each tailored to meet the specific torque demands of each joint.

With peak torques exceeding 380 N.m (280.3 ft.-lb.), the FSA 2.0 actuators boost GR-2’s agility and dynamic capabilities. The dual-encoder system doubles control accuracy, ensuring precise movements even in high-pressure environments.

Designed for both speed and precision, FSA 2.0 empowers GR-2 to navigate complex tasks with greater flexibility, said Fourier.

Fourier optimizes tools for open-source software development

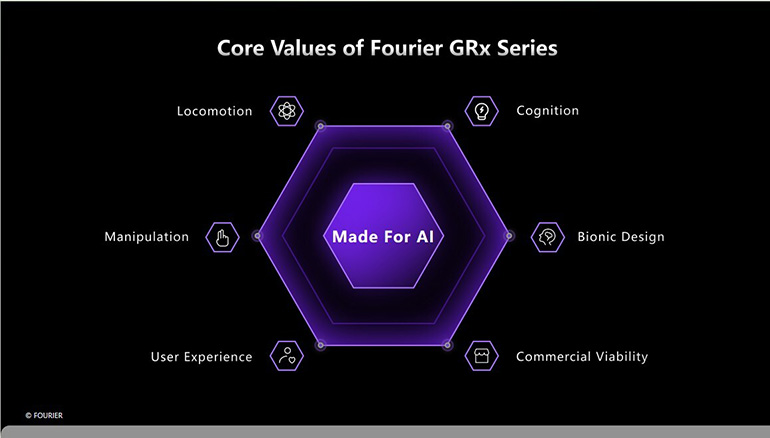

Fourier GRx series outlines six key areas for humanoid development—locomotion, manipulation, cognition, bionic design, user experience, and commercial viability. | Credit: Fourier

Fourier optimized GR-2’s development platform by introducing a new software development kit (SDK) compatible with programming languages such as ROS. Developers can access a suite of pre-optimized modules for machine vision, path planning, and force feedback control through application programming interfaces (APIs), said the company.

Supporting frameworks such as NVIDIA Isaac Lab and Mujoco, the new platform empowers developers to focus on innovation, streamlining their workflows, claimed Fourier.