|

Listen to this article |

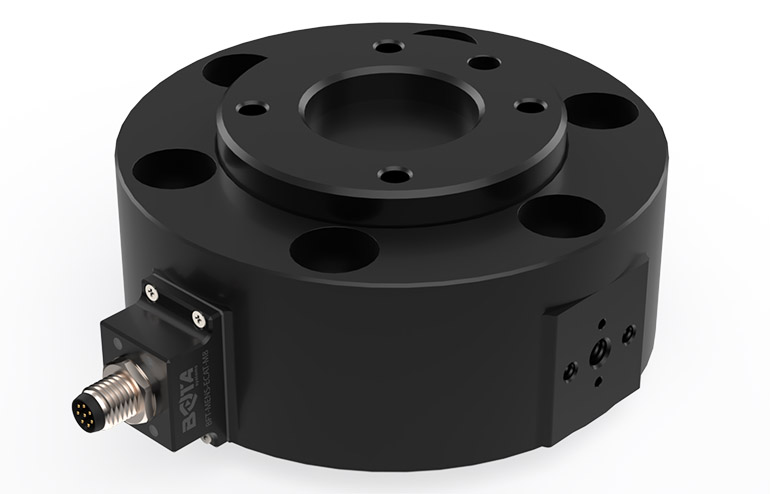

Bota Systems AG, a developer of multi-axis, force-torque sensors, last week launched the SensONE T80. The Zurich-based company said it designed its latest sensor for larger collaborative robots. The SensONE T80 features ISO-standard flanges on both sides and is intended to simplify integration and ensure accuracy even with heavier payloads.

The SensONE T80 is equipped with ISO-9409-1-80-6-M8 flanges. These directly match the mounting flanges on the latest cobots from Universal Robots, eliminating the need for an adapter. Bota Systems said this eliminates the need for additional engineering to design adapter mounting equipment, significantly reducing time to market.

The sensor also includes an ISO 9409-1-50-4-M6 flange to accommodate third-party devices compatible with Universal Robots, facilitating the development of new interfaces.

“This sensor, featuring ISO flanges on both sides, is a perfect fit for the UR20 and UR30 models,” said Susanne Noerdinger, the head of ecosystem success for Europe, the Middle East, and Africa (EMEA) at Universal Robots.

“It provides a high-precision, direct-fit solution that simplifies integration for our customers, enabling them to leverage the full capabilities of our cobots in demanding applications like heavy palletizing and welding,” she added. “This collaboration with Bota Systems increases the sensitivity and precision of solutions with UR, giving our customers the tools they need to innovate and automate more effectively.”

The SensONE T80 sensor is designed for easy integration with UR cobot arms. Source: Bota Systems

A lighter sensor means more payload capacity, says Bota Systems

A robotic force-torque sensor measures force and torque applied to its surface. Using these real-time measurements in feedback control enables robots to perform complex interaction tasks with precision.

Bota Systems said that by removing the need for an adapter, the overall weight of the sensor assembly is minimized. This allows the robot’s payload capacity to be fully used for material handling rather than simply supporting end-of-arm tooling.

In addition, the elimination of adapters reduces the risk of using inappropriate materials that could compromise sensor stiffness and affect measurement accuracy, the company noted.

“The SensONE T80 is particularly beneficial for applications such as heavy palletizing and tightening tasks (typically handled by the UR30) and welding (common for the UR20),” stated Klajd Lika, co-founder and CEO of Bota Systems. “Additional applications include large-scale sanding and polishing, precision mechanical assembly, and face matching/alignment of heavy workpieces, such as in CNC loader operations.”

The SensONE T80 can handle up to 80Nm of torque. Its peak-to-peak noise (measured at six times the standard deviation) is 0.3N for force measurements and 0.012Nm for torque, achieving the same precision levels as sensors used for lower-payload cobots.

Bota Systems said its torque range supports the full payload capacities for cobots including the 25 kg and 35 kg capacities recently introduced for the UR20 and the UR30, respectively.

Products at RoboBusiness, Customer Experience Center

Spun out of ETH Zurich in 2020, Bota Systems said its SensONE sensors enable human-machine interaction and can provide force, vision, and inertia data. The company, which exhibited at RoboBusiness last week, said its sensors can be used in a variety of robotics applications, including rehabilitation, precision assembly, product testing, polishing and grinding, and surgery.

In April, Bota Systems launched PixONE, a sensor that brings together high-performance electronics with a compact, lightweight design. The company said it designed these sensors for “seamless integration into robotic systems.”

PixONE features a through-hole architecture facilitating internal cable routing to enhance robot agility and safety, claimed the company.

Bota Systems also announced a new Customer Experience Center at at HEIDENHAIN’s CONNECT Manufacturing Innovation Hub in Fremont, Calif. The new center will show its complete portfolio of force-torque sensors alongside a Mecademic robot demonstrating cutting-edge applications. Visitors can see how these sensors can optimize robotic performance in a range of industrial settings.

The Customer Experience Center at HEIDENHAIN Connect Innovation Hub in California. Source: Bota Systems