|

Listen to this article |

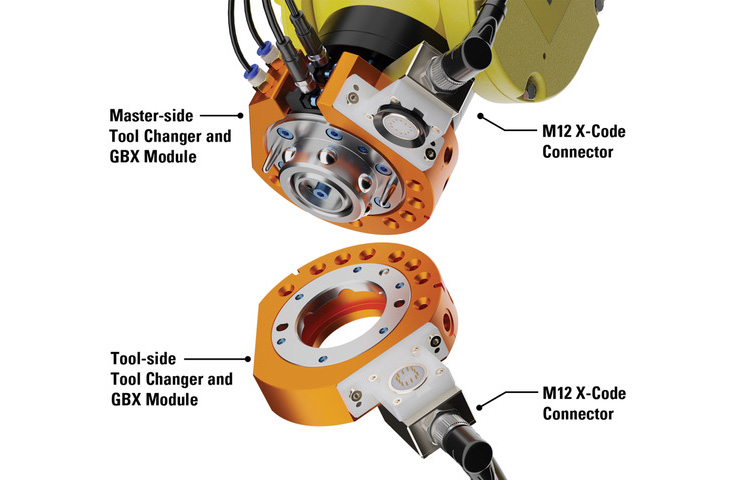

The GBX Ethernet Module includes plug-and-play connectors for pass-through of Cat6/Cat6a industrial Ethernet cables. | Source: ATI Industrial Automation

ATI Industrial Automation today announced the GBX 10 Gigabit Tool Changer Ethernet Module. The company said it designed this module to optimize performance and flexibility of smart manufacturing processes with timely, accurate communication.

When industrial robots first joined production lines, manufacturers expected a robot to repeatedly perform a single task for hours on end, noted ATI. Now, as end users look for more flexibility in their operations, they increasingly expect robots to not only perform a variety of tasks, but also to be able to seamlessly switch between those tasks on their own.

This is where tool changers, which allow robots to automatically change end effectors or other peripheral, come into play, said the company.

Robotic tool changers help users get the most out of their robots, assuming they work quickly and seamlessly. Every second a robot spends changing over a tool is a second not spent doing the task at hand, according to ATI.

GBX 10 module designed for multiple applications

ATI said its Ethernet module provides safe and reliable transmission of high-speed data, signals, and fieldbus communication for advanced automation and artificial intelligence. It claimed that the new module provides signal communications for a variety of industries and applications, including vision, inspection, metrology, motion control, and fieldbus systems.

Additional features and benefits of the GBX 10 Gigabit Tool Changer Ethernet Module include:

- Plug-and-play M12 8-pin X-code connectors for safe and reliable pass-through of Cat6/Cat6a industrial Ethernet cables, saving time during integration, with no stripping, crimping, or soldering required

- Configurable cable exit options between -90°, 0°, and +90° radial positions, allowing users to optimize cable dress and routing to reduce cable strain and maximize system uptime

- Superior longevity, handling up to 1 million mating cycles to support applications in advanced industries such as automotive, aerospace, testing, and more

- Broad compatibility with ATI-standard tool changers, heavy-duty tool changers, and utility couplers for widespread module standardization

The GBX 10 Gigabit Ethernet tool changer provides connectivity for a range of robot applications. Source: ATI Industrial Automation

About ATI Industrial Automation

Apex, N.C.-based ATI is a developer of robotic accessories. Its products include automatic tool changers, multi-axis force/torque sensing systems, utility couplers, material removal tools, robotic collision sensors, manual tool changers, and compliance devices.

Founded in 1989, the company said it aims to develop cost-effective, state-of-the-art end-effector products that improve robotic productivity.

In November 2023, the company released the MC-50 Manual Tool Changer, which it said provides high performance, reliability, and quality for the manual exchange of robotic tooling. This compact and robust Tool Changer is designed for applications on collaborative robots that support payloads up to 25 kg (55.1 lb.), and small industrial robots supporting payloads up to 10 kg (22 lb.).