|

Listen to this article |

The study looked at how electrician tasks such as cable pulling could be automated in Denmark. | Source: AI generated, via HowToRobot

In a construction site in Denmark, two electricians grapple with a stubborn cable, their arms stretched overhead as they maneuver it into place. But today, they’re not alone – two robot engineers watch intently, their minds already racing with possibilities. Could a machine assist with this physically demanding task, allowing a single electrician to do the job of two?

The scene unfolded as part of a new initiative that could significantly impact Denmark’s electrical contracting industry. As the country faces a growing shortage of skilled electricians, industry leaders are exploring a novel solution: robots and automation.

To map out the industry’s automation potential, the trade union Dansk El-Forbund and employers’ association TEKNIQ Arbejdsgiverne commissioned an independent study by HowToRobot. The consultancy said it revealed the potential for robotics to address the pressing labor challenges facing the industry:

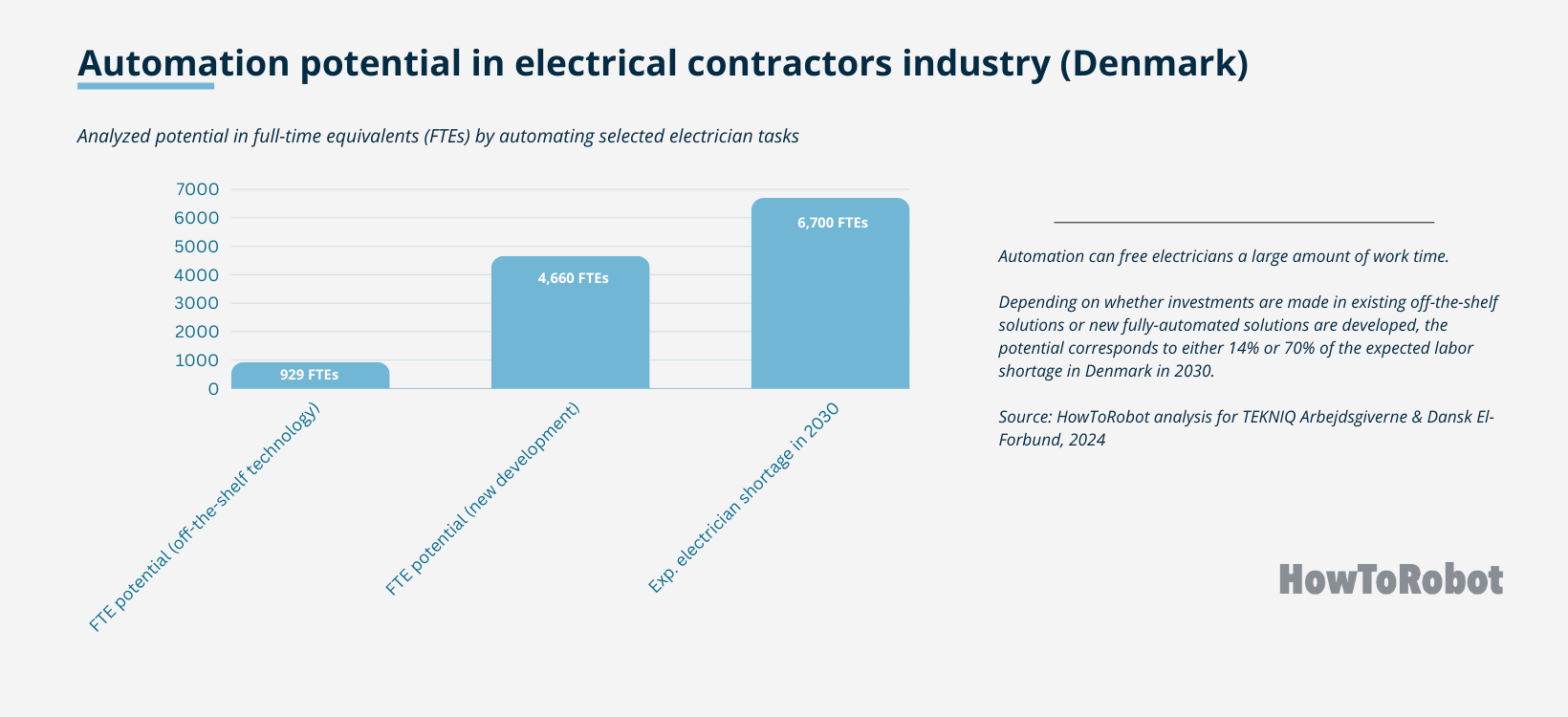

- By 2030, Denmark is projected to face a shortfall of 6,700 electricians.

- Implementing existing off-the-shelf technologies could address 14% of the expected electrician shortage by 2030.

- With the development of new, fully automated systems, up to 70% of the expected shortage could be addressed.

“There is already a shortage of labor in the industry, and the green transition increases the need for electricians even further,” said Maria Schougaard Berntsen, deputy director of TEKNIQ Arbejdsgiverne. “This study shows that automation could be a key part of the solution.”

Denmark’s electrician shortage increases need for automation

The shortage of skilled labor is affecting many Danish industries, but electrical contractors are particularly hard hit. Thirty-seven percent of electrical contracting companies said they experience “production restrictions” due to a lack of labor. That’s far more than the 24% for the general industry, according to Statistics Denmark data from May.

Electricians are also among the occupational groups in Denmark that companies have the hardest time recruiting. Just over a third of all advertised electrician positions end up with unsuccessful recruitment, according to the Danish Agency for Labor Market and Recruitment.

“This increased demand puts additional pressure on the current electricians in the industry to work more with the risk of getting worn out faster,” said Lars B. Sørensen, area manager at Dansk El-Forbund.

The companies participating in the demonstration project said they hoped to find ways to free electricians from the heaviest, most monotonous, and repetitive tasks. This goal has been successfully achieved, according to Mikkel Viager, a robot engineer from HowToRobot. He observed and analyzed more than 50 electrical installation and maintenance tasks as part of the project.

“We uncovered a wide range of existing, often semi-automatic, aids and solutions that can reduce the time electricians spend on many of their tasks,” he said. “It was far more significant than we had dared to hope.”

The project identified 13 electrical tasks across renovation, maintenance, and new construction as suitable for automation and optimization with new or existing technology. In particular, the study found great potential in automating processes such as cable pulling behind ceilings and walls, hole drilling for electrical installations, measuring and marking, and channel cutting for wiring.

“The analysis shows enormous potential. Automation can help ensure that a company can say yes to orders that they would otherwise have to decline due to staff shortages,” said Schougaard Berntsen. “This debunks the myth that robots are taking jobs from people.”

A graph showing the analyzed potential in full-time equivalents by automated selected electrician tasks in Denmark. | Source: HowToRobot

Automation reduces heavy and tedious tasks

One thing is to automate to optimize work time, but in the bigger picture, there are other considerations motivating electrical contracting companies.

“What appeals to me most about automation is that we can spare our employees and reduce wear and tear. Some of those entering the labor market now will be working until they are over 72 years old. If they are to stay in the industry, we need to take good care of them,” says Jesper Timming, Managing Director of the Danish electrical contractor Linde-El – one of the companies studied in the project.

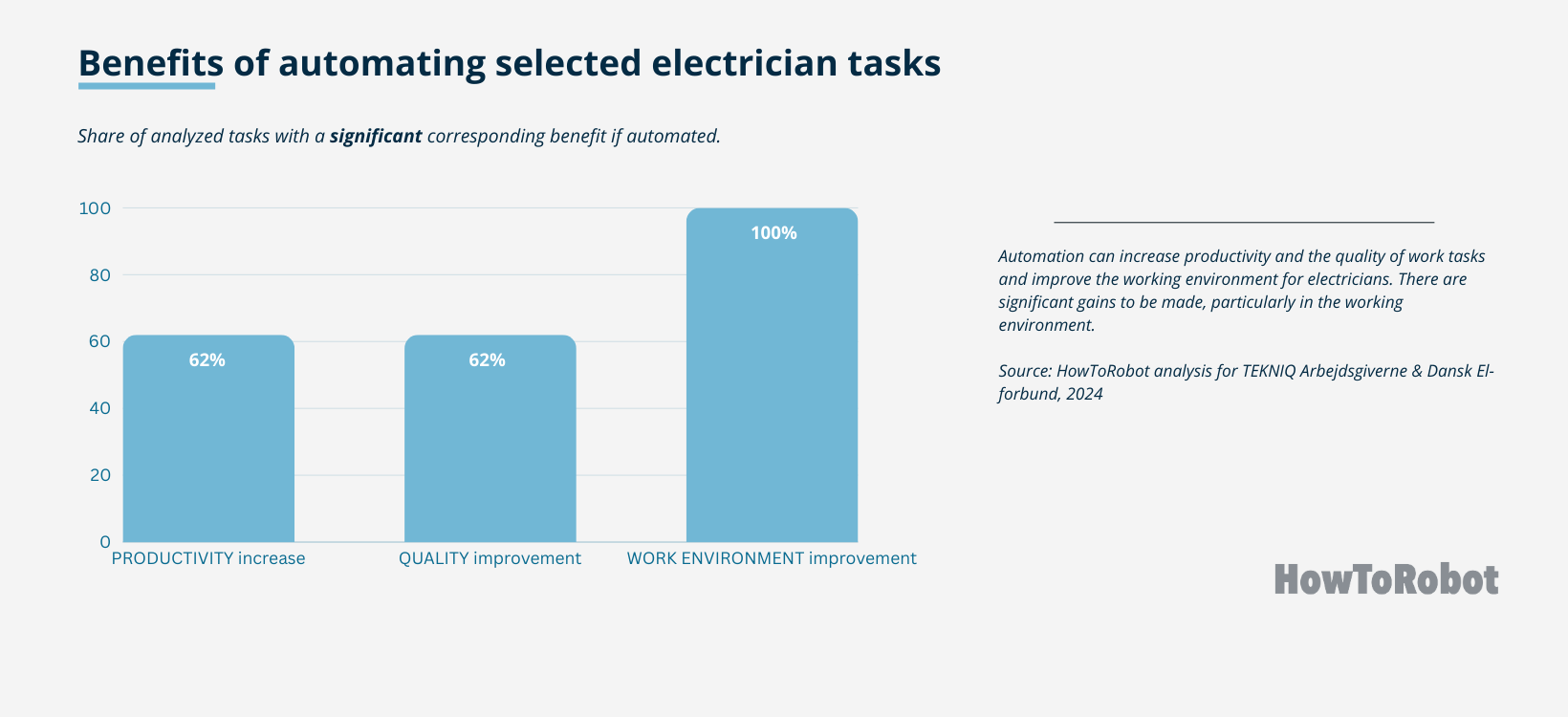

Particularly heavy tasks in difficult working positions, such as working on ladders with hands above shoulder height, can be wearing – especially on the shoulders. One of the project’s goals was, therefore, to map out how automation can help reduce the number of wearing tasks and thus improve the working environment. Across the tasks analyzed, the study found an ‘improved working environment’ to be the overall most significant positive effect of automation.

A graph showing the share of analyzed tasks with a significant corresponding benefit if automated in Denmark. | Source: HowToRobot

Measurement, grooving: Much, but not all, can be automated

During the project, several electrician tasks beyond cable pulling emerged as suitable for automation.

One of these was the measurement and marking of placements for sockets, conduits, etc. Various existing systems can reduce the time spent on these tasks and minimize measurement errors.

However, an automated system using a 3D scanner could scan a room and then plot installations directly from a technical drawing onto walls, floors, and ceilings for marking. In addition, there are mobile robots that can print the drawing directly on the floor.

Another task that HowToRobot identified during the project was drilling holes in ceilings and walls for sockets, cable routing, and installation. Drilling is both a dusty and noisy process that often involves poor working positions for electricians.

During the project, a range of off-the-shelf tools were found that can ease the work – from simple drills for making square holes for embedded sockets to more advanced mobile drilling robots.

A third electrician task identified in the project was channel cutting for concealed cable routing. This task is typically noisy, dusty, and time-consuming, and a higher degree of automation can, therefore, improve both the working environment and free up work time for electricians.

Regardless of the task to automate, electrical contractors should aim to find a balance and focus on what provides the most value for money, recommended Viager.

“Although almost everything can theoretically be automated, it is rarely a good idea to aim too high,” he said. “When you break a task down into smaller parts and look at the technologies available on the market today, you might find a reasonable solution that can handle a portion of the task, which can still be hugely valuable.”

Danish union, association map electrician automation opportunities

The project involved experts from HowToRobot following electricians at work and analyzing their tasks in consultation with company management and the performing electricians. Although the consultancy’s approach is best known in the manufacturing industry, it has increasingly found applications in other sectors where automation is gaining ground, such as healthcare and agriculture.

“With a systematic review of the opportunities and a thorough knowledge of the technologies and the supplier market, you lay the foundation for sensible investments that help boost both the company’s bottom line and employees’ job satisfaction,” said Viager.

HowToRobot said its process systematically maps both the opportunities, benefits, and risks of implementing robotics in the work. As part of the electrician project in Denmark, each of the participating companies received a report that gave management an overview of its automation potential.

One of the companies is currently exploring the development of a mobile robot to assist with pulling and pushing cables. Several are exploring how other existing systems can help electricians do a range of tasks more effectively and safely.

Participants highlighted one of the key benefits of the projects: the process of involving both management and employees in exploring new opportunities and ways of working.

“It is interesting to see that when employees and employers sit down together and ask what they can do smarter — a fantastic list of ideas and opportunities emerges on how they can make the workplace a better place,” said Sørensen.

Schougaard Berntsen acknowledged the importance of bringing expertise in robotics and automation to the electrical contracting industry.

“The project has confirmed that if you do not know the technologies, it can be difficult to see where the potential lies,” she said. “When you look at it from a different professional perspective, it becomes clear that there is a great untapped potential to become more automated and use robot technology in the industry today.”

Mobile drilling robots can aid electricians but may require some adjustments at construction sites. | Source: AI generated

How new sectors can get started with robotics

Viager offered the following advice for companies looking to get started with automation:

1. Start by getting an overview of the possibilities. Avoid locking yourself into a particular technology or solution too quickly, but focus on what is most needed. It’s also a good idea to consult with your employees and find out if you have some ambassadors who can help drive the project and push it forward.

2. Get out in the field, and assess the potential for automating individual tasks. This can rarely be done from an office alone. Get experienced tech people with knowledge of the market and solutions to scrutinize the tasks. The aim is to look broadly at all the tasks and find the common denominators – and then be realistic about what can be done and whether the business case holds up.

3. Consult the market on what is possible. When you have a clear idea of your needs, describe them. Avoid designing the solution in advance, but describe the need and the task you want to automate and ask relevant suppliers. Sometimes, there will be existing off-the-shelf solutions; other times, it will require developing something new.

“Typically, 80% of the gain can be harvested for 20% of the cost,” Viager added. “Trying to achieve 100% level of automation, the price to reach the last 20% will often be disproportionately high.”

Editor’s note: This article was syndicated from HowToRobot.