|

Listen to this article |

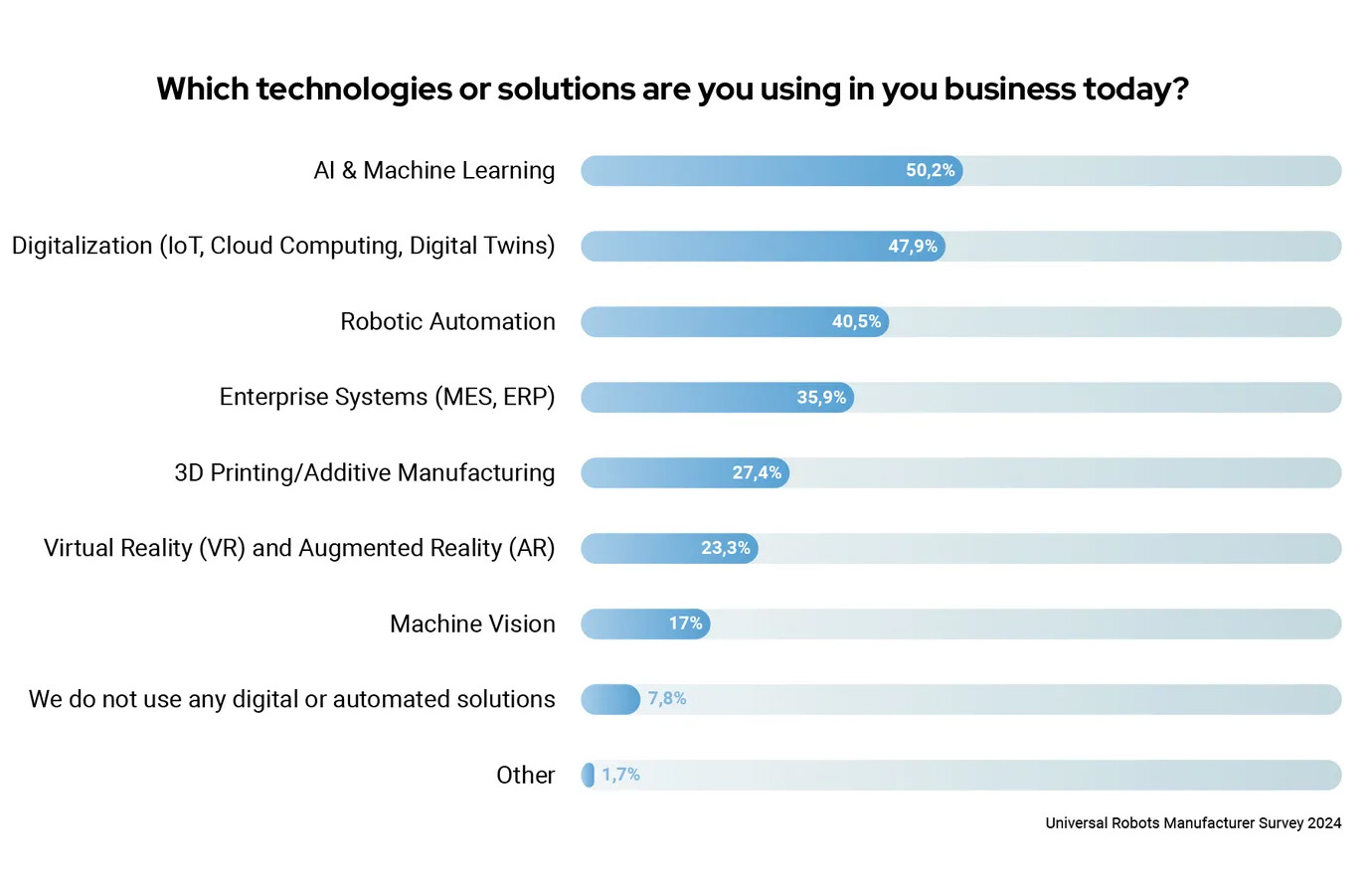

The UR survey showed companies are increasingly using AI and machine learning, and digitalization, in their businesses. | Source: Universal Robots

The artificial intelligence market is projected to reach $407 billion by 2027, with an annual growth rate of 37.3%, according to Forbes. To shed light on this growing market, Universal Robots A/S, or UR, recently asked nearly 1,200 manufacturers across North America and Europe how they use the technology and how they plan to invest in the future.

More than 50% of respondents said they already use AI and machine learning in their production.

“AI isn’t just hype,” stated Anders Billesø Beck, vice president for strategy and innovation at Universal Robots. “Though it may only have become a common topic of conversation within the last two years, AI and machine learning are now critical drivers of innovation and efficiency in today’s manufacturing.”

Looking forward, 48% of manufacturers plan to further invest in AI and machine learning by 2025, indicating that these technologies will continue to play a pivotal role in the future of manufacturing. With a confidence rate of 99%, the survey gathered responses from seven different countries in Europe and North America.

The participants represented 569 large enterprises and 278 small and midsized companies. They came from various industries, primarily manufacturing, healthcare, food and beverage, and automotive.

Universal Robots said the survey shows that AI and machine learning are recognized as critical technologies for current operations and future investments. The Danish collaborative robot company predicted that AI-powered robotic systems will become more prevalent across industries.

Inside the UR survey results

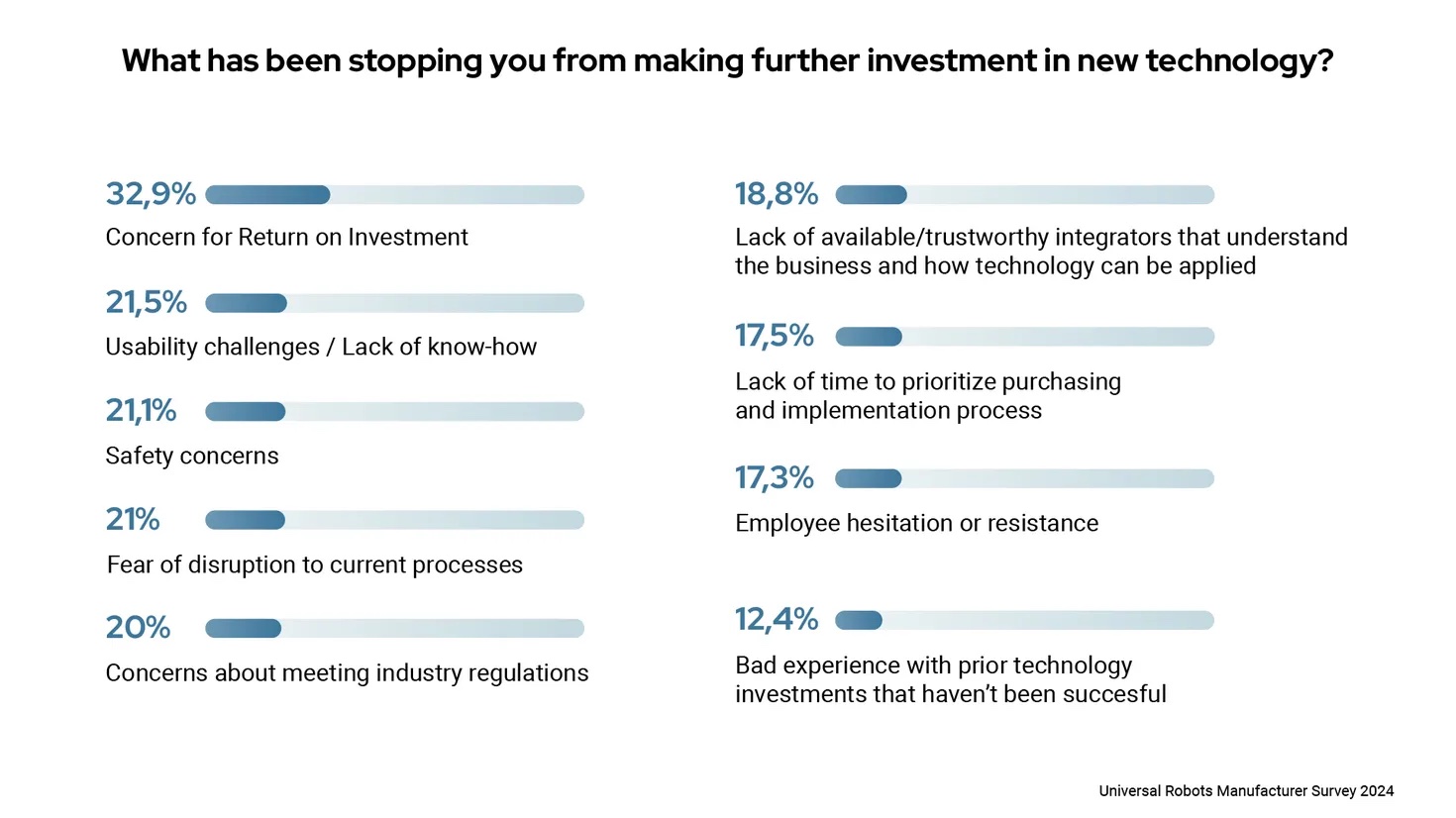

The UR survey showed concern for return on investment was the highest concern for respondents. | Source: Universal Robots

Universal Robots also said the survey indicates the evolving importance of digitalization, with 47% of manufacturers currently using technologies like the Internet of Things, cloud computing, and digital twins. These tools can help manufacturers optimize operations, reduce downtime, and save costs through simulations and predictive maintenance.

Digitalization also enables manufacturers to shift towards more resilient, high-mix production models that better meet market demands, said UR.

Over 50% of respondents identified improving product quality, increasing productivity, and enhancing accuracy as top reasons for embracing new technologies. UR asserted that this demonstrates industry’s commitment to using robotics and AI to improve performance and competitiveness in the market.

In addition, 30% of manufacturers surveyed said they are using technology to improve working conditions, and 26% are driven by sustainability goals.

While return on investment (ROI) remains the primary concern for 32% of manufacturers, other factors such as usability, in-house expertise, safety, and potential disruptions were also significant (all around 20%).

As automation and AI gain more traction, manufacturers have increasingly prioritized ease of use as a key factor when investing in technologies. Forty-seven percent of respondents said that it’s of greatest importance to them that technologies are straightforward to integrate and operate.

This was closely followed by reliability. Other factors cited by the survey respondents include modularity, sustainability, fast deployment, and predictive maintenance.

Editor’s note: Eric Truebenbach, managing director of Teradyne Robotics Ventures, will participate in panels on the future of robotics innovation and robotics investment trends at RoboBusiness 2024, which will be on Oct. 16 and 17 in Santa Clara, Calif. Teradyne is the parent company of Universal Robots and Mobile Industrial Robots.