NREL researchers developed a technique to weld the glass of solar panel modules with a femtosecond laser.

Solar panels are built to last 25 years or more in all kinds of weather. Key to this longevity is a tight seal of the photovoltaic materials. Manufacturers achieve the seal by laminating a panel’s silicon cells with polymer sheets between glass panes. But the sticky polymer is hard to separate from the silicon cells at the end of a solar panel’s life, making recycling the materials more difficult.

Researchers at the U.S. National Renewable Energy Lab (NREL) in Golden, Colorado say they’ve found a better way to seal solar modules. Using a femtosecond laser, the researchers welded together solar panel glass without the use of polymers such as ethylene vinyl acetate. These glass-to-glass precision welds are strong enough for outdoor solar panels, and are better at keeping out corrosive moisture, the researchers say.

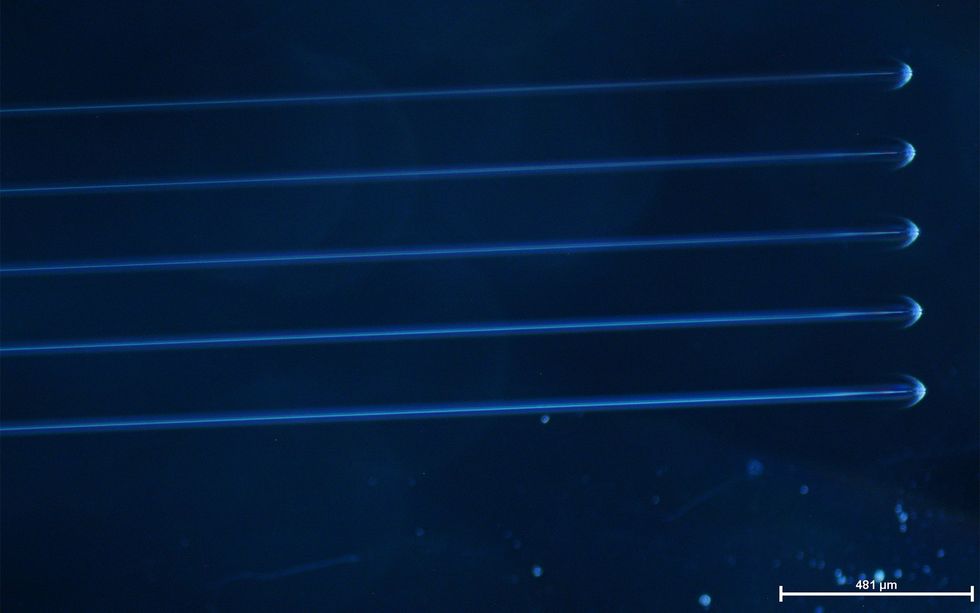

A femtosecond laser welds a small piece of test glass.NREL

A femtosecond laser welds a small piece of test glass.NREL

“Solar panels are not easily recycled,” says David Young, a senior scientist at NREL. “There are companies that are doing it now, but it’s a tricky play between cost and benefit, and most of the problem is with the polymers.” With no adhesive polymers involved, recycling facilities can more easily separate and reuse the valuable materials in solar panels such as silicon, silver, copper, and glass.

Because of the polymer problem, many recycling facilities just trash the polymer-covered silicon cells, and only recover the aluminum frames and glass encasements, says Silvana Ovaitt, a photovoltaic (PV) analyst at NREL. This partial recycling wastes the most valuable materials in the modules.

“At some point there’s going to be a huge amount of spent panels out there, and we want to get it right, and make it easy to recycle.” —David Young, NREL

Finding cost-effective ways to recycle all the materials in solar panels will become increasingly important. Manufacturers globally are deploying enough solar panels to produce an additional 240 gigawatts each year. That rate is projected to increase to 3 terawatts by 2030, Ovaitt says. By 2050, anywhere from 54 to 160 million tonnes of PV panels will have reached the end of their lifespans, she says.

“At some point there’s going to be a huge amount of spent panels out there, and we want to get it right, and make it easy to recycle. There’s no reason not to,” says Young. A change in manufacturing could help alleviate the problem—although not for at least another 25 years, when panels constructed with the new technique would be due to be retired.

In NREL’s technique, the glass that encases the solar cells in a PV panel is welded together by precision melting. The precision melting is accomplished with femtosecond lasers, which pack a tremendous number of photons into a very short time scale–about one millionth of one billionth of a second. The number of photons emitted per second from the laser is so intense that it changes the optical absorption process in the glass, says Young. The process changes from linear (normal absorption) to nonlinear, which allows the glass to absorb energy from the photons that it would normally not absorb, he says.

The intense beam, focused near the interface of the two sheets of glass, generates a small plasma of ionized glass atoms. This plasma allows the glass to absorb most of the photons from the laser and locally melt the two glass sheets to form a weld. Because there is not an open surface, there is no evaporation of the molten glass during the welding process. The lack of evaporation from the molten pool allows the glass to cool in a stress-free state, leaving a very strong weld.

A femtosecond laser creates precision welds between two glass plates.David Young/NREL

A femtosecond laser creates precision welds between two glass plates.David Young/NREL

In stress tests conducted by the NREL group, the welds proved almost as strong as the glass itself, as if there was no weld at all. Young and his colleagues described their proof-of-concept technique in a paper published 21 February in the IEEE Journal of Photovoltaics.

This is the first time a femtosecond laser has been used to test glass-to-glass welds for solar modules, the authors say. The cost of such lasers has declined over the last few years, so researchers are finding uses for them in a wide range of applications. For example, femtosecond lasers have been used to create 3D mid-air plasma displays and to turn tellurite glass into a semiconductor crystal. They’ve also been used to weld glass in medical devices.

Prior to femtosecond lasers, research groups attempted to weld solar panel glass with nanosecond lasers. But those lasers, with pulses a million times as long as those of a femtosecond laser, couldn’t create a glass-to-glass weld. Researchers tried using a filler material called glass frit in the weld, but the bonds of the dissimilar materials proved too brittle and weak for outdoor solar panel designs, Young says.

In addition to making recycling easier, NREL’s design may make solar panels last longer. Polymers are poor barriers to moisture compared with glass, and the material degrades over time. This lets moisture into the solar cells, and eventually leads to corrosion. “Current solar modules aren’t water tight,” says Young. That will be a problem for perovskite cells, a leading next-generation solar technology that is extremely sensitive to moisture and oxygen.

“If we can provide a different kind of seal where we can eliminate the polymers, not only do we get a better module that lasts longer, but also one that is much easier to recycle,” says Young.