|

Listen to this article |

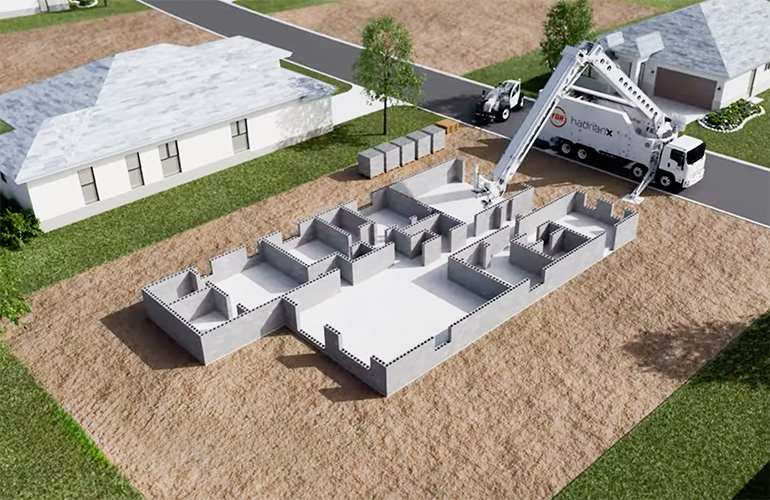

The latest generation of the Hadrian X brick-laying robot arrived in the U.S. to begin a demo program. | Credit: FBR

FBR is developing an automated bricklayer robot for large building construction projects. The Hadrian X bricklaying robot features a huge mechanism attached to a vehicle that delivers each brick to the end effector through the structure of the robot arm. The Australia-based company has been commercializing products for the construction sector since 1994.

In the fall of 2023, Hadrian began building the next generation of its bricklaying robot. This next-gen Hadrian X was fitted to a U.S.-certified truck chassis to be delivered to a construction partner in Florida. The first unit of FBR’s next-generation Hadrian X arrived at port in Florida this week.

The robot will undergo an engineering assessment to ensure its readiness for site acceptance testing. The unit will then begin a demonstration program, based in Florida, for U.S.-based contractors to evaluate the unit. It will construct between 5-10 single-story houses with Demonstration Program partner CRH Ventures.

The company will offer the Hadrian X through a “Walls as a Service” program, whereby local contractors can hire the solution to be deployed on a building site for the construction of the walls. The Hadrian X doesn’t apply mortar between the bricks while placing them. Once the wall is completed, a strong construction adhesive is applied to bond the individual bricks in place, and the company claims that this is stronger than old-school mortar construction.

Bricklaying automation is evolving

Autonomous bricklaying competitor Monumental raised $25 million earlier in 2024. Following pilot test cases in the Netherlands, Monumental completed its first large-scale, 15-m (49.2-ft.) facade for an office and warehouse building in 2023.

Housing is in huge demand around the world and manual bricklaying is a highly skilled trade that is unfortunately not keeping up with demand as the current generation of bricklayers retire. Automation solutions like FBR and Monumental are growing quickly to fill the gap in demand.